Orientation Check – Customised Vision Solution

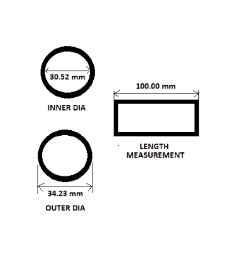

At Unseen ERA, our Orientation Check solution is a high-performance customised vision system that has been developed to verify that a product is present in the correct orientation before processing through critical processes such as packaging, assembly, pick-and-place operations, or robotic handling.

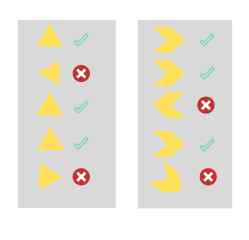

In an automated manufacturing setting, even a slight error in orientation can cause assembly rejects, machine downtime, or expensive rework. The Orientation Check solution ensures that every product is properly aligned, transferring only those parts that are oriented correctly, while automatically rejecting those that are not, resulting in increased efficiency, accuracy and throughput.

Reliable Orientation Verification for Automated Lines

The Importance of Orientation Verification in Automated Manufacturing Using the Open ERA’s Orientation Inspection System is Clearly Evident Today, where Speed and Precision Matter. Open ERA’s systems employ state-of-the-art algorithms to identify error conditions in product orientations immediately. Each product orientation is checked to eliminate orientations incompatible with robotic handling, conveyor systems, or pick-and-place applications.

By Identifying Incorrectly Oriented Products Early in the Production Process, Manufacturers will Experience Substantially Decreased Downtime, Reduced Material Waste, and a Decrease in the Number of Quality Failures Would Create Significant Opportunities to enhance the Overall Quality of their Products.

Orientation Performance – High Speed & Reliability

Built for use in the most demanding production environments, the Open ERA Orientation Verification System inspects parts at inspection speeds of up to 800 units per minute due to its ability to provide rapid and accurate decision support without sacrificing accuracy. This capability makes Open ERA’s Orientation Verification System Ideal for Utilisation in High Volume Manufacturing Lines with Fast, Consistent Decision Making Required.

Smart Data Handling & Compliance-Ready Software

This product solution was built to provide operational efficiencies and to comply with both government regulations and industry standards for data integrity through continuous monitoring, analytics, and traceability (both in real-time and offline). Using software that complies with the regulations of Title 21 Code of Federal Regulations (21 CFR), this software solution is compliant for use within regulated environments, including the pharmaceutical, medical device, and food processing industries, where record-keeping for data integrity and audit trails is of utmost importance.

Image Storage and Recipe Management

The Orientation Check solution includes a storage option, enabling manufacturers to save an image of their inspection of a specific product and use it for historical quality analyses, troubleshooting, and documentation for compliance. The recipe management component permits the manufacturer to quickly change from one product or stock-keeping unit (SKU) to another, thus creating a very versatile solution for manufacturing operations that have a high degree of variability among products produced.

Key Features

- Inspection rates up to 800 parts per minute

- Ability to automatically detect and reject products that are not properly oriented

- Connectivity to either the cloud or an offline (local) server

- Compliant software as defined by Title 21 CFR for regulated industries

- Storage option for images used to document compliance and quality control

- Recipe management system, providing rapid changeover between products

- Designed to be integrated into an existing automated and robotics system

Typical Uses for Orientation Check

- Pick and Place Automation

- Automatic Checking and Sorting of Products

- Identifying Mixed or Oriented Incorrectly Product

- Counting Good vs. Bad Parts

- Inspection of Pre-Assembly and Pre-Packaged Parts

- Robotics and Automated Positions Handling

Why Choose Unseen ERA for Customised Vision Solutions?

At Unseen ERA, we provide custom vision inspection systems for manufacturers that solve real-world issues in production through the design and integration of our Orientation Check. The Orientation Check is designed for maximum integration into existing automation systems, and provides a technology that complies with industry requirements while offering superior speed, dependability and compliance. Whether you want to increase quality control by decreasing errors or optimise robotic systems, Unseen ERA’s Orientation Check offers a dependable and scalable vision system for the Industry 4.0 market.

Frequently Asked Questions About the Orientation Check Vision System

Question 1. What is the purpose of the Orientation Check?

Answer. The Orientation Check is designed to ensure that all products are correctly orientated before they are sent for packaging, assembly, or robotic processing, thus reducing mistakes and increasing system performance.

Question 2. What types of industries will benefit from using this product?

Answer. Within the automotive, electronics, FMCG, pharmaceutical, and food processing industries, the Orientation Check can be used to increase quality and the efficiency of automation systems.

Question 3. How quickly can the Orientation Check inspect parts?

Answer. The Orientation Check can inspect up to 800 parts per minute, making it ideal for high-speed production lines.

Question 4. Is the Orientation Check’s software compliant with industry standards?

Answer. Yes, the Orientation Check comes with software that is 21 CFR compliant and therefore suitable for use in regulated industries, including pharmaceuticals, medical devices and food processing.

Call

Call Whatsapp

Whatsapp Contact Us

Contact Us