In today’s innovative and high-tech environment, optical character recognition, or software critical components, are the key players in a machine vision system. OCR scans all the text and written characters from the image, while OCV ensures that all critical text is properly aligned with predefined standards. Those technologies combined can easily reduce manual efforts and save time. In this guide, we will discuss OCR/OCV Industrial Printers Maximizing Labeling Efficiency

This OCV machine vision system reduces manual inspections, streamlines operations, and effectively enhances productivity. Businesses that implement this OCR system can save 20 hours per week. Industrial printing systems can reduce operational costs by up to 30% by implementing these tools.

What Are The OCR and OCV Industrial Printers?

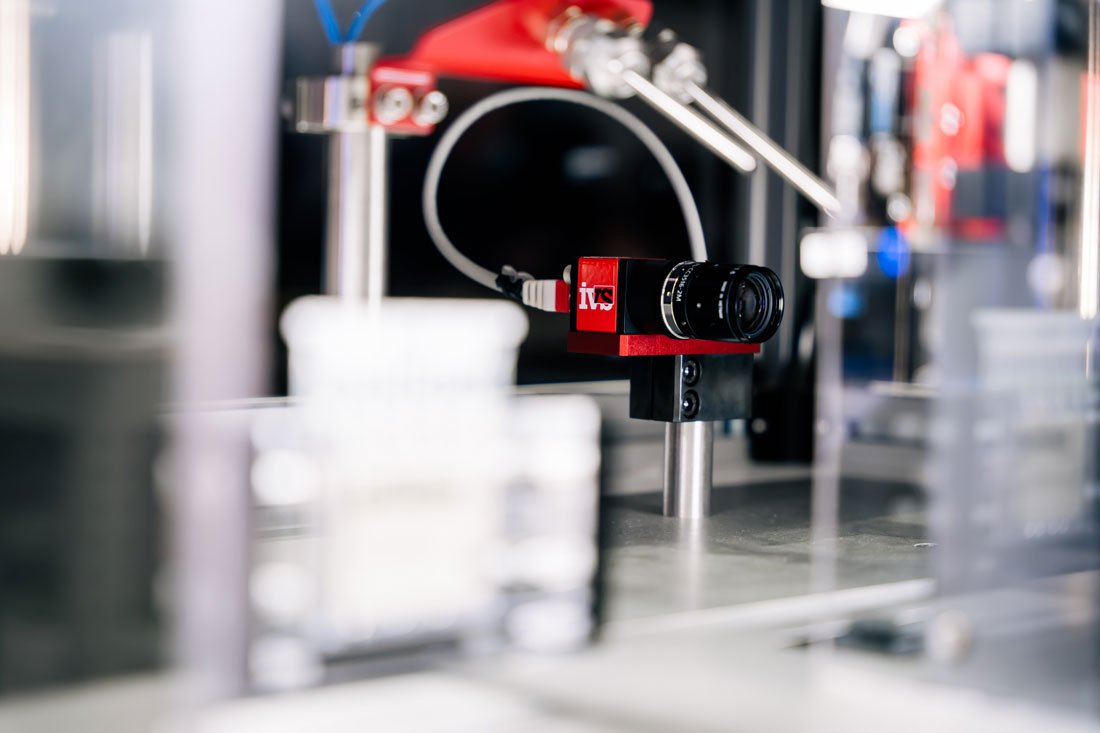

In industrial vision systems, the OCR is mostly used for tracking quality controls and automation. These automation sensors read all images, texts, numbers, or symbols. The camera captures images and detects all texts. This is mostly verified and traced in product lines.

OCR printers are designed to verify the correctness of printed labels and characters used in packaging. The OCV printing system is based on AI technology and intelligent software. This system detects all errors, like color, misprinted text, and real-time monitoring of all defective products.

When these two work together in combination, they become the best and most effective solution, which maintains labeling efficiency and preserves the product’s wattage.

What Is The Significance Of Labeling In Industrial Production?

Proper and accurate labeling is the face value of every product. It is the easiest component in operational efficiency because of the OCR & OCV industrial printers.

- Ongoing observance: It is important to note that various industries, such as pharmaceuticals, food and beverage, and electronics, have strict labeling standards. Facing errors in their labeling patterns can decrease the goodwill of the company in front of customers. This system ensures the batch number, expiry dates, or serial codes from packing labels.

- Product traceability: Labels are the most important and the first component for tracking products within the supply chain. Efficient labeling helps track product batches, enabling the company to measure the quality and quantity of manufacturing batches.

- Enhance customer confidence: when the company supplies proper and accurate information about its products. So it increases the trustworthiness and builds a brand reputation.

- Business efficacy: effective and efficient labeling ensures and minimizes downtime or increases the flow of smooth production. These OCR and OCV sensors continuously reduce human errors.

How Can OCR & OCV Industrial Printers Maximize Labeling Efficiency?

- Automatic label detection: these printers do the detection process or verify all the printing labels. or reducing the manpower or manual inspections. Manual inspections can slow down production, but an industrial label verification system reduces waste and protects the company’s goodwill.

- Handling fluctuating data: variable data printing in industrial systems ensures the batch numbers, serial controls, or QR codes. This system ensures the different information of every batch without slowing down the production line. It is especially suitable for high-volume manufacturing and customized vision solutions.

- Monitor quality in real time: this system gives real-time alerts while it detects any kind of error in the production line. So the manufacturer or workers can fix the printing or errors. It is also known as real-time labeling inspection.

- Incorporation between product systems: this system easily connects with ERP and MES, and it makes reports for every batch or regulates quality standards. Their data operations easily drive data operations.

- Reduce manual inspections: OCR&OCV system eliminates human errors from automated labeling verification. Or it mainly focuses on reducing labor costs and enhancing productivity.

What Are The Applications Of OCR & OCV Industrial Printers?

- Pharma industry: Pharma companies need to verify materials with expiry dates and regulatory labels. These printers detect minor labeling issues because of the wrong medical consequences.

- Food and beverage industry: it analyzes the production units’ expiry dates, batch numbers, or ingredient information when it is not printed correctly, so it eliminates and gives alerts.

- Automotive and electrical industry: these sensors track serial numbers, part identification, or traceability through the supply chain.

- Customer goods and packaging: It supports manufacturers’ customized labeling with many variations, which causes a slowdown in production.

Why Choose Unseen Era OCR/OCV Industrial Printers Maximize Labeling Efficiency

Choosing the right labeling solution can be challenging. Unseen Era is the perfect solution for all your production, labeling, and manufacturing processes in your business. We deliver various industrial sensors that detect all errors, unmatched quality, reliability, or support.

What Are The Benefits Of Choosing Unseen Era?

- Unseen Era specializes in industrial automation and packaging labeling solutions. We understand the challenges of high-speed product lines. Our experts’ solutions provide you with the best OCR & OCV fits for your workflow.

- We provide you with the AI-driven technology to increase labeling accuracy and efficiency.

- Our experts provide you the proper guidance to choose the right solutions for your industry.

- We have future-driven technology that recognizes real-time analytics for your solutions.

Winding up

In today’s competitive environment, adopting AI-driven technology ensures the proper packaging and provides you the powerful solutions to increase productivity activities. Unseen Era offers you variable data handling and a real-time data monitoring solution.

People Also Ask OCR/OCV Industrial Printers Maximize Labeling Efficiency

Q.1 What is the difference between OCR & OCV industrial printers?

A: The OCR printers read all the texts and numbers while printing the manufacturing or OCV, ensuring the correctness of labels.

Q.2 Does this OCR & OCV reduce wastage?

A: Yes, absolutely, it reduces the errors and reprints in the manufacturing or production lines. It ensures optimized material use.

Q.3 How does it reduce manual inspections?

A: It reduces manual inspections because it analyzes and reads the labels of products. Because it monitors and analyzes the correctness, expiry dates, and ingredients.

Q.4 Do these OCR & OCV printers support barcode scanners?

A: Yes, these printers fully support barcode or QR scanners. It ensures the proper labeling and packaging and reduces errors.

Call

Call Whatsapp

Whatsapp Contact Us

Contact Us