Measurements – Customised Vision Solutions

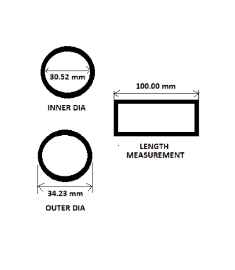

Unseen ERA has developed automated measurement systems with ultra-precision and high-speed potential to meet the strict measurement requirements of today’s manufacturing environments. The Measurements Vision System, part of Unseen ERA’s Customised Vision Solutions, provides an automated measuring solution designed to support consistent quality in product and control of processes, and to provide for ultra accurate and fast measuring results.

Designed for use in today’s manufacturing environments, this solution is for moving manufacturers away from sampling parts to 100% inline measurement capabilities, thereby ensuring that all components are manufactured to the exact specifications.

Precision Measurement for Quality-Driven Manufacturing

The growing demand for high-precision and quality-driven products in many industries, such as automobile parts, precision engineering, etc., necessitates the use of accurate and consistent measuring/calibrating methods. Unseen ERA’s automated, vision-based measuring solutions allow manufacturers to measure components down to 10 microns and provide superior repeatability and accuracy to the manufacturing process.

Human intervention in measuring should be eliminated to reduce the chances of fatigue errors and to provide for equal quality in every manufactured product.

Fast Automated Inspection

The Measurements Vision System product is designed to work in a high volume production environment with inspection rates up to 500 parts/min. The system allows for quick, accurate measurements without stopping or slowing the manufacturing process.

- Automated measurements:

- Higher-Speed Inspection Cycles

- More Accurate, Consistent Measurements

- Fewer Manufacturing Bottlenecks

- Increases Overall Equipment Effectiveness (OEE)

100% Product Inspection for Improved Reliability

Traditional Product Quality Inspection uses a sampling technique to assess quality. Using a vision-based measuring system offers total product quality inspection. This provides:

- The Ability to Detect Dimensional Variations Early

- Reduced Rework and Scrap

- Increased Customer Satisfaction

- To Improve Compliance with Quality Standards

Advanced Data Management & Compliance Ready

The Measurement Vision System is designed to provide a platform for the requirements of Digital Manufacturing and Regulatory Compliance. The Measurement Vision System connects easily with Cloud-based and Offline Services, Providing Real-time Data Access, Traceability, and Long-term Performance Analysis. For Industries Subject to Regulation, there is a Version of all Software that complies with 21 CFR, thus allowing the use of the Measurement Vision System for Applications Requiring An Audit Trail and Data Integrity.

Key Features

- Measurement Resolution (Ultra-high): Accuracy of up to 10 microns.

- Inspection Speed (High): Measure up to 500 parts per minute

- Data Storage and Analysis (Cloud & Offline): Secure data storage and analysis capabilities.

- Quality System (21 CFR Compliances): This software is suitable for the manufacturing of regulated products.

- Traceability & Quality Audit (Image Storage): Allows traceability of all measurements and audits of quality-related issues.

- Product Changeover (Recipe Management): Easy changeover of products and specifications during production.

- Automation of Operations (Full Automation): All automated operation reduces the amount of human intervention required and fatigue experienced by operators.

Extensive Range of Industrial Uses

Unseen ERA’s vision measurement solution can be customised for the industry’s diverse range of applications as well as for any type of product. This includes the following:

- Measure automotive parts.

- Measure precision components.

- Food industry/applications include measuring the length, width and thickness of a chocolate bar.

- Inspect consumer goods.

- Custom industrial measurement applications.

The vision measurement system can be designed to accommodate specific product dimensions, tolerances and environmental conditions.

Why Choose Unseen ERA for Customised Vision Measurements?

Unseen ERA provides customised vision measurement systems created specifically to meet the real-world needs of manufacturers. We combine high-resolution imaging, advanced algorithms and manufacturing-grade reliability to ensure you achieve the highest level of accuracy, fastest possible production and the greatest possible scalability in production.

For accurate, repeatable and fast measurements, Unseen ERA’s Measurement Vision System provides a solution that is focused on the present and future of your business, whilst supporting continuous improvement initiatives and Industry 4.0 objectives.

FAQs About Customised Measurements Vision Solutions

Question 1: How accurate is the Measurement Vision System?

Answer. Unseen Era’s Measurement Vision System is accurate to within 10 microns, allowing Unseen Era to offer a solution for any high-precision requirement, including the automotive and precision manufacturing industries.

Question 2: Which industries are most likely to use Unseen Era’s Measurement Vision System?

Answer. Automotive manufacturers, component manufacturers, food processors, and suppliers to the consumer goods industry are just a few of the many industries that are currently utilising Unseen Era’s Measurement Vision System.

Question 3: Does Unseen Era’s Measurement Vision System provide data storage and traceability?

Answer. Our Vision System provides the ability to store both image data and measurement data, allowing manufacturers to easily conduct quality audits, track traceability, and analyse their processes.

Question 4: Is Unseen Era’s Measurement Vision System customizable for specific applications?

Answer. At Unseen Era, we provide customised vision solutions, allowing manufacturers to develop and implement a solution that is specific to their product and their production conditions by customising the hardware, software, and measurement logic.