Imagine your machines suddenly break down, and you don’t have enough budget to repair them immediately. Can you really afford such a huge loss? Probably not. That’s why you need to know how AI is minimizing unplanned downtime in your industries. Many companies have already adopted this AI technology, which allows them to easily detect every error before it turns into a bigger problem.

If you’re also looking for Predictive Maintenance Systems, or Artificial Intelligence in Industry, you’re in the right place. In this blog, we’ll discuss how AI helps minimize unplanned risks and predictive maintenance systems: How AI is minimizing unplanned downtime.

What is a predictive maintenance system in AI?

Predictive maintenance AI is a modern approach that analyzes your machine effectively. At the same time, it identifies how the machine was performing earlier and how it is performing at present. It also alerts you before the machine breaks down, indicating if there is any issue or fault in the machine. Predictive maintenance is a method that gives early warnings before a machine fails. This AI technology not only helps prevent damage, but it also helps to increase the lifespan of machinery.

How does an AI predictive maintenance system work?

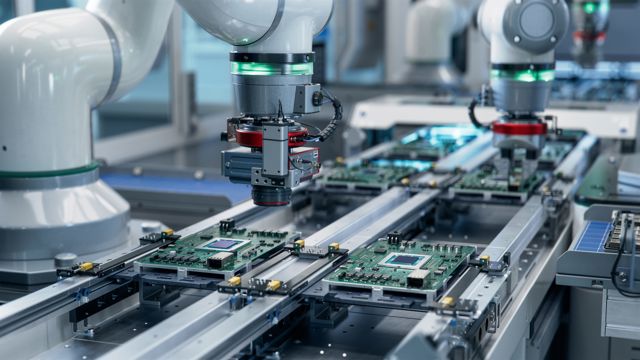

This AI predictive system is surpassing older technology. Previously, we used to operate machines manually and set a fixed schedule for them, which meant there was no regular inspection or monitoring. As a result, machines would easily break down, and the risk of accidents increased. But nowadays, machines and technology have become so advanced that you don’t even need regular maintenance. If any problem occurs in your machine, automated sensors will immediately notify you, allowing you to minimize unplanned downtime.

Real-time data collection

This AI predictive maintenance system analyzes your machine and collects real data from your machines. Automated AI sensors are specially designed to monitor your machines and they compare the old working time with the new working time. And gives you a proper health report of the machinery.

- Temperature of machinery

- Oil and grease levels

- Air pressure

- Heating conditions

- Machine sliders

- Electric motors

It reduces manual inspections and minimizes the manpower needed to analyze machinery conditions.

Data analysis or pattern recognition

Industrial AI solutions just do not collect data, but they also learn machine learning functions like historical or real-time monitoring. It shows you the machinery patterns to indicate problems, or shows you the current machine data. It easily analyzes early fault detection.

How does it analyze machine Errors:

- It analyzes vibration changes or motor analysis, like a rotating bearing.

- Temperature measurement or Greece problems.

- Detects heating problems due to high friction.

Anomaly prediction

When an AI recommendation system analyzes and detects all errors or machine learning algorithms. Once it detects errors such as component failure, oil leakage, or any condition that could cause the machine to fail, it immediately sends alerts. These sensors mostly use their statistical data to analyse errors or detections.

How it calculates:

- When any part is likely to fail

- High-risk parts

- It reduces unplanned downtime with AI

Optimize Maintenance Schedule

AI automation sensors analyse their real-time sensors like vibration, humidity, or pressure. An AI system detects machine maintenance and the actual health report of machinery.

- If the machinery is healthy, the machinery will run continuously and will not give any warning.

- When it requires maintenance, machines give you signs for maintenance immediately.

- When any part of the machine fails soon so AI automation technology gives you the plan to replace the slot.

Benefits:

- Less unnecessary downtime

- Less maintenance cost

- Long life of the machine

- Enhance productivity

Automatic alerts and smart support

This automated system not only gives you machinery failures, but it also communicates with you and provides you with all solutions for machinery.

- Handset notifications

- Email alerts

AI learning concept

Automated technology has a special feature: it is always learning and making improvements to its automated technology. AI analyzes every machine’s data and saves its routine on a daily basis.

- False alarm decrease

- Timely reminder for maintenance

- Early predictions eliminate unexpected breakdowns.

What are the key benefits of AI predictive maintenance?

- Reduce machine failure because AI sensors give a reminder before they fail.

- It is a cost-saving formula because it has fewer chances of requiring maintenance.

- Reduce the chances of accidents or faults in machinery.

- Increase machinery lifespan.

- Increase productivity through better resource management.

Which industries use the AI predictive system used in?

- An AI predictive maintenance system is used in manufacturing industries like motors, conveyor belts, and compressors. It analyzes every small detail.

- Uses in the oil and chemical industry, like pumps, drill machines, and tubelines. It analyzes leakage in the oil industry that causes a reduction in accidents.

- Wind turbine and generator, this AI automation system is used in the power and energy sector.

- An AI predictive system helps in the healthcare sector, like MRI, ventilators, and CT scans.

Why choose the Unseen Era for a predictive maintenance system?

In the AI automation industry, Unseen Era is the leading company that delivers its automation services in various industries. Our AI predictive maintenance system is specially designed to enhance productivity and reduce accidents in the manufacturing units. At Unseen era we provide you, Industrial Sensors, safety products.

Perks of choosing Unseen Era.

- AI-generated accuracy

- Seamless integration

- Mobile alerts

- Cost saving

- Increase safety

- Dedicated support

People Also Ask About The Predictive Maintenance Systems: How AI Is Minimizing Unplanned Downtime?

Q.1 How does an AI predictive maintenance system reduce employee workload?

A: This AI predictive maintenance system reduces manual inspections and inspects machines in advanced technology. An AI predictive maintenance system focuses on the machine’s faults and workload.

Q.2 Does this AI predictive maintenance system help to save energy?

A: This reduces unnecessary usage of machines and analyzes whether machines are working properly or not. An AI predictive maintenance system reduces energy consumption or supports an eco-friendly environment.

Q.3Does the AI predictive maintenance system make wrong predictions?

A: AI automation technology is specially innovated for learning and developing concepts. It properly understands the machine structure or working algorithms so that the prediction is highly accurate.

Q.4 Does an AI predictive maintenance system work without the internet?

A: Some AI sensors are working without the internet; when the internet is available, it is useful for mining and remote factories.

Call

Call Whatsapp

Whatsapp Contact Us

Contact Us