In the evolution of the fast or modern world. All the manufacturers continuously struggle to enhance their product designs, production, or delivery. Did you know that these days are gone, such as smoky or energy-hungry factories? Across industries are moving into the smart, and achieving green factories in the future. These are designed to reduce carbon emissions and optimise the performance of the overall industrial automation system.

If you want to know about the industrial automation & green factories, stay tuned. In this article, we will explore how AI automation, IoT sensors, and robotics are transforming traditional manufacturing industries into smarter and more efficient operations.

Demand For An Industrial Automation System?

According to business research insights, the global industrial automation market is currently US$209.9 billion in 2025, and it is expected to grow to US$474.5 billion by 2035, with a CAGR of 8.5%.

Why Does Sustainability Matter In The Future Of Automation?

The manufacturing industry is one of the highest energy consumers in the world, and it is responsible for global greenhouse gas emissions in a huge chunk of the world. Higher energy costs and growing environmental concerns have become a business priority. That’s why the industrial automation system not only matters in enhancing productivity, it’s all about enhancing energy-efficient, data-driven, or eco-friendly, responsible systems.

What Are Green Factories?

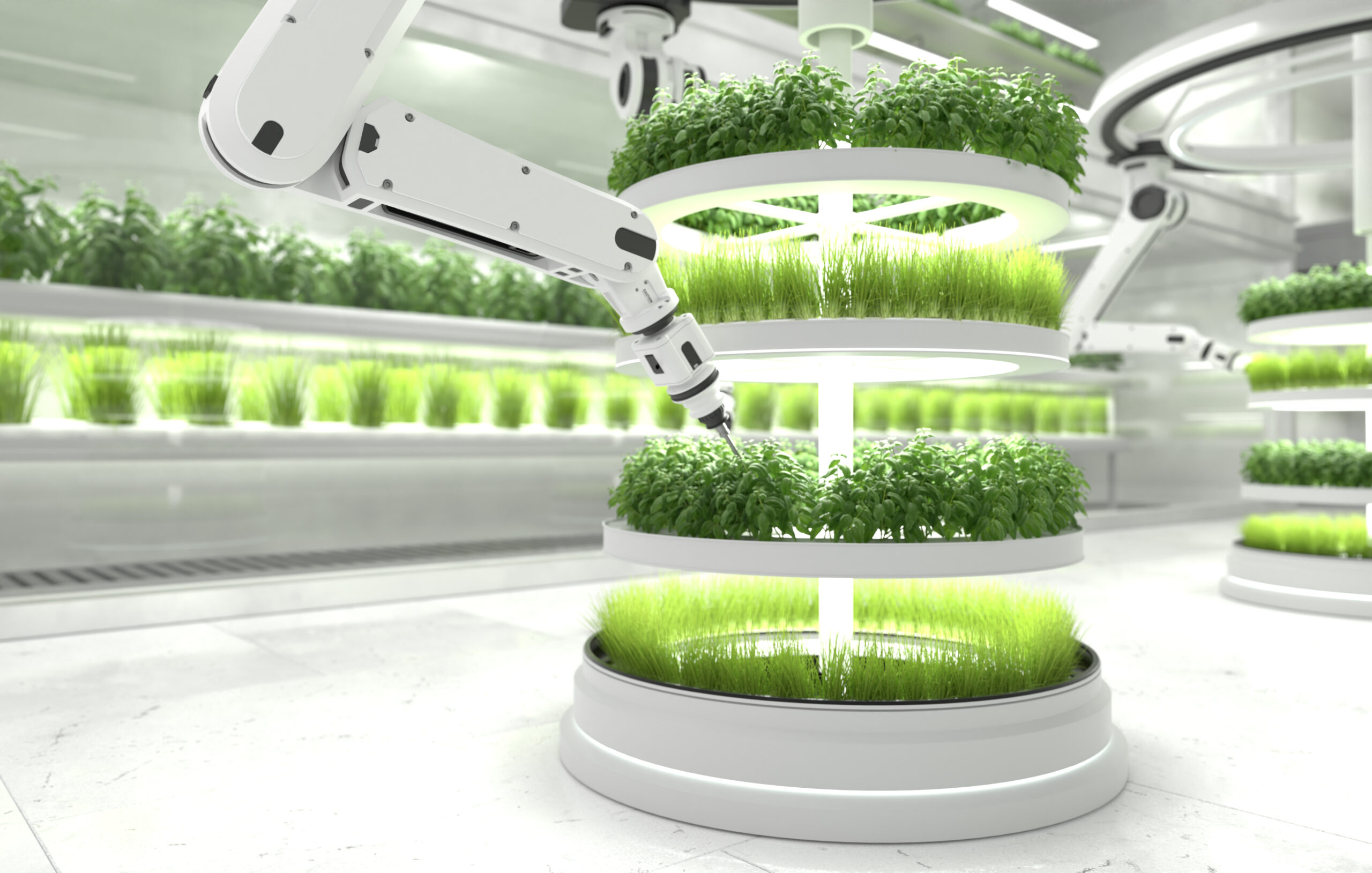

What did you think about green factories, such as smart manufacturing, renewable energy, or automation technologies that reduce the footprint or smartly boost productivity? Yes, you are absolutely right, the green factories enhance production without smartly affecting the environment.

What sets these factories different:

- IoT sensors for real-time monitoring

- Predictive maintenance to reduce wastage and breakouts

- AI-powered robotics with precision manufacturing

- Working with a digital twin system to enhance production

- Energy-efficient control system with smart analysis

Various companies and industries use greenhouse solutions to enhance production and profitability, in go hand in hand.

How Does Industrial Automation Help To Build Sustainable Manufacturing?

The industrial system helps to build sustainable manufacturing, reduce energy wastage, and enhance overall efficiency.

- Improve energy efficiency: the smart machinery automation system works with machine learning algorithms that monitor every energy consumption unit or analyze material, workers’ behavior in real time. When we take an easy example, such as the smart industrial sensors automatically adjusting the fan’s speed to save energy without optimizing performance.

- Reduce wastage: the smart automation system works with predictive maintenance, or IoT sensors to track all machinery behaviour with minimizing wastage, reducing maintenance cost, or extending the equipment lifespan.

- Enhance production with a digital twin system: the digital twin system enhances the virtual process of production. The twin sensor system saves both materials and energy.

- Cutting emissions with smart robotics: these industrial automation systems help to detect every minor error, reduce energy wastage, and defects. The AI-based system easily cuts down the cost of manufacturers with material wastage, or reduces the overall carbon emissions.

- Integrating renewable energy: there are various factories using solar panel systems, battery storage systems in the industrial automation setup. The smart grids easily balance the renewable energy with higher productivity demands.

Why Is Industry 4.0 The Smart Backbone Of Green Factories?

The fourth industrial revolution is easily transforming and working with AI, IoT, and cloud-based systems to create an effective environment in self-optimizing product systems. When it connects with a traditional machinery system, it enables real-time data monitoring & energy-efficient production systems. This smart system helps various factories to optimize their performance and efficiency at every stage of manufacturing.

What Are The Benefits Of A Smart Backbone In Green Factories?

- Industry 4.0 can easily track energy consumption in real time

- This automation system predicts environmental impact in real time.

- Enhance efficiency or improvements

- Easily reduce emissions automatically

- When we say in a simple way, industrial automation makes factories smarter and faster.

People also ask about Sustainability in Industrial Automation: Green Factories of the Future

Q.1 How does industrial automation help to enhance my factory manufacturing?

A: The industrial automation sensors easily enhance your factory production by improving overall efficiency, accuracy, or consistency. These automation systems reduce human errors and optimize resources to ensure better quality control.

Q.2 How much of the industrial twin system cost?

A: The average cost of the industrial automation twin system depends on the size, complexity, and integration levels, such as $50,000 to over $500,000, depending on the industry automation goals.

Q.3 Do the industrial automation green factories boost factory workers’ performance?

A: The green industrial automation easily boosts workers’ performance by ensuring safe, clean, and more effective environments by removing odor smells, humidity, and improving overall efficiency.

Q.4 Does this industrial automation system easily audit the production in the manufacturing industry?

A: The industrial automation system easily audits the production by providing real-time data analytics, and it shows the production lacks, performance analysis, and transparency in manufacturing.

Call

Call Whatsapp

Whatsapp Contact Us

Contact Us