Laser & distance sensors play a major role in automation, manufacturing, and food processing industries. Ultrasonic vs. Laser Distance Sensors Both sensors work with the same technologies, with their advantages and limitations. If your robots and tank connectors are facing problems measuring objects, this article is especially for you. In this blog, we will discuss Ultrasonic vs.Laser Distance Sensors: Which Suits Your Use Case?

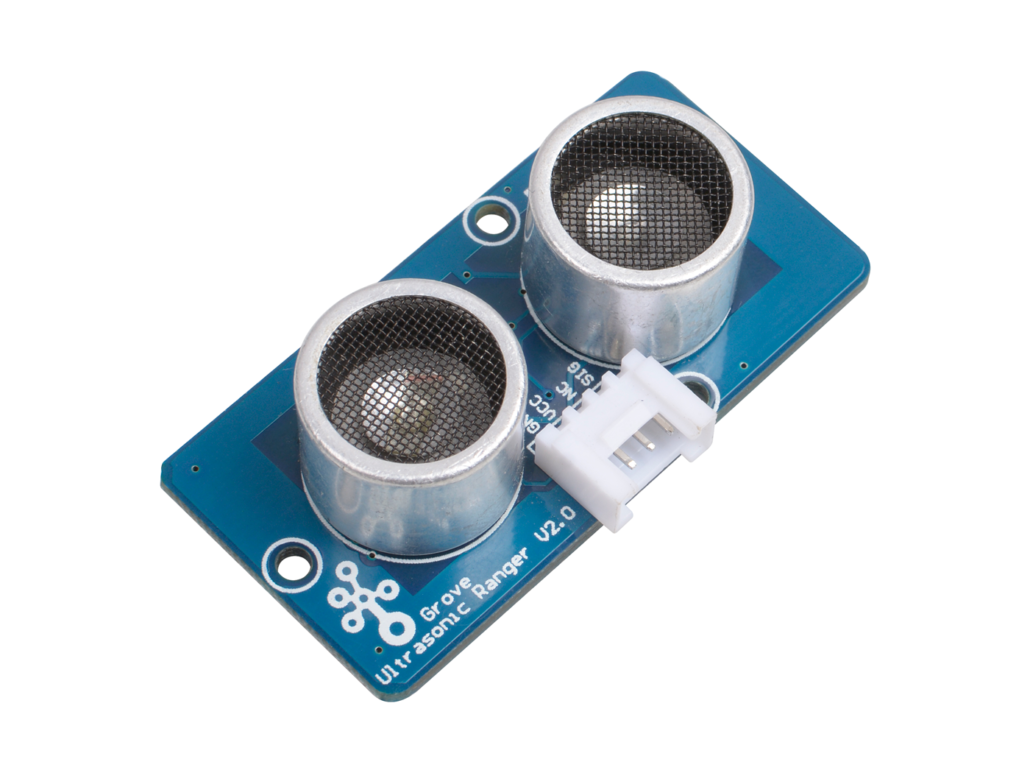

How Do Ultrasonic Sensors Work?

The ultrasonic sensors produce ultrasonic sounds to measure object distances. This sensor targets the high-frequency sound waves that can easily calculate the distances of the sound bump and return. These special features make the ultrasonic sensors a preferable choice for every industrialist. Ultrasonic sensors are widely used in robotics, automation, and various industrial applications.

Most of the favorable features of ultrasonic sensors are easy to use and work effectively in dusty and low-light environments. This makes it the most popular choice for small or huge industrial workplaces.

What Are The Benefits Of Ultrasonic Distance Sensors?

- Accurate distance measurement

- Cost-effective solution for every industry

- Simply adaptable & easy to use

- Reliable performance

- Ideal for the robotics and automation industry

- It detects contactless measurements

What Are The Applications Of Ultrasonic Sensors?

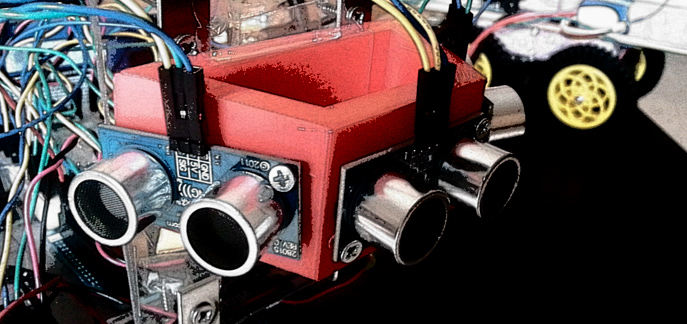

- Helping robots detect obstacles

- Smart home devices

- Construction sites distance measurements

- Medical equipment

- Monitor water and oil tanks

How Do Laser Distance Sensors Work?

Laser distance sensors are famous for their distance user-focused laser beam. This is also known as a LiDAR sensor that reflects an object back and calculates the time of laser travel. This laser sensor is capable of long measurement, fast response, and high accuracy in industrial, construction, automation, and vehicle safety systems. This laser distance sensor is also used in 3D mapping applications.

What Are The Benefits Of Applying A Laser Distance Sensor?

- Contactless safe measurement

- Faster response without any errors

- Highly accurate performance in industrial environments

- Easy to adapt and install

- Boosts productivity

- Requires less maintenance and longer lifespan

- Detect minor errors easily

What Are The Applications Of Laser Distance Sensors?

- This sensor is highly capable of measuring manufacturing and automation distances.

- For construction sites, it measures the distances for land surveying.

- Used in robotics for autonomous systems with high precision.

- It also contributes to agriculture and machinery guidance.

- This sensor makes 3D models of autonomous vehicles.

Key Difference Between Ultrasonic Vs. Laser Distance Sensors

Both Ultrasonic & Laser Distance Sensors are widely used in measuring objects in various industries. These graphs help you to know the difference between technology, accuracy, and measurements.

| Feature | Ultrasonic Distance Sensor | Laser Distance Sensor |

| Working Principle | It works with high-frequency sound waves that calculate the object distance with bounce time. | It works with a laser beam system that calculates time with light reflection. |

| Measurement Range | It is mostly suitable for 5 to 10 meters. | This is mostly used in long-term measurements. |

| Accuracy | It delivers proficient accuracy with a few millimeters. | It provides high accuracy with a long diameter. |

| Speed of Response | It is slightly slow because of the building surfaces. | It provides past responses with lightning speed. |

| Environmental Performance | Works in all dusty, rusty, and dark environments, because lights and dust can not affect sound waves. | Performance is not affected by dust and snow particles |

| Object Detection | It detects large surfaces that struggle with smart, thin, and soft materials. | It detects small objects |

| Cost | This is affordable for every industrial space, making it a budget-friendly option. | This is more expensive due to higher technology. |

| Applications | Used in the robotics industry, parking sensors, and proximity detection | This is most commonly used in construction, industrial, and autonomous vehicles. |

| Maintenance | Less maintenance, durability | It requires occasional maintenance. |

| Power Consumption | Consume less electricity | High power consumption because of the laser components |

Ultrasonic Vs. Laser Distance Sensors: Which Suits Your Case?

If you think about implementing a laser and ultrasonic industrial sensor so it will depend on your application environment and the facility usage.

When your industry requires a low-cost and durable short-medium sensor that is easy for your employees to use, ultrasonic distance sensors are the most beneficial choice for every industrial application. It detects liquids, oils, chemicals, and various obstacles. This sensor works in dusty, lightless, and most humid weather conditions.

When you need a less costly, durable, long-range application so you need the laser sensor is a smart choice for measuring long-range distance. It is suitable for industrial, robotics, and autonomous vehicles.

In short

- For long range, choose a laser distance sensor

- For short range, choose an ultrasonic distance sensor

People Also Ask About Ultrasonic Vs. Laser Distance Sensors

Q.1 Which sensor works accurately in my manufacturing industry?

A: It depends on the type of your manufacturing industry because of various applications in your manufacturing environment. A laser distance sensor is the best choice for quality control and faster response time. The ultrasonic distance sensor is suitable for measuring liquid forms in dusty and uneven conditions.

Q.2 Which sensor is a budget-friendly solution for the automation industry?

A: The ultrasonic sensor is budget budget-friendly solution for your industry, but it measures only 5 to 10 meters distance, only if your requirement is high, so you need to choose a laser distance sensor that measures long obstacles and performs accurately.

Q.3 How can I choose the right sensor for my construction site?

A: It totally depends on the construction site, measurement needs, and safety. If your project needs long measurements, you need to choose a laser distance sensor. Whether you need a short distance for the oil industry, you can go with an ultrasonic laser distance sensor.

Q.4 Does the ultrasonic distance sensor work underwater & chemical environments?

A: Yes, this sensor works in underwater & chemical environments because of its sensor design, frequency, and build quality.

Call

Call Whatsapp

Whatsapp Contact Us

Contact Us