Are you facing problems in your packaging unit, because of low speed, packaging errors, or a lack of packaging quality? Then you need to adapt flow wrap machines that have completely revolutionized your packaging unit. No matter whether you run the food and beverage industry, pharmaceuticals, or any kind of manufacturing unit. Flow-Wrap Packaging Machines Optimizing Packaging Speed & Flexibility for all types of production units.

If you want to explore flow wrap packaging machines: optimizing packaging speed & flexibility. Stay tuned to this blog.

What Are The Flow Wrap Packaging Machines?

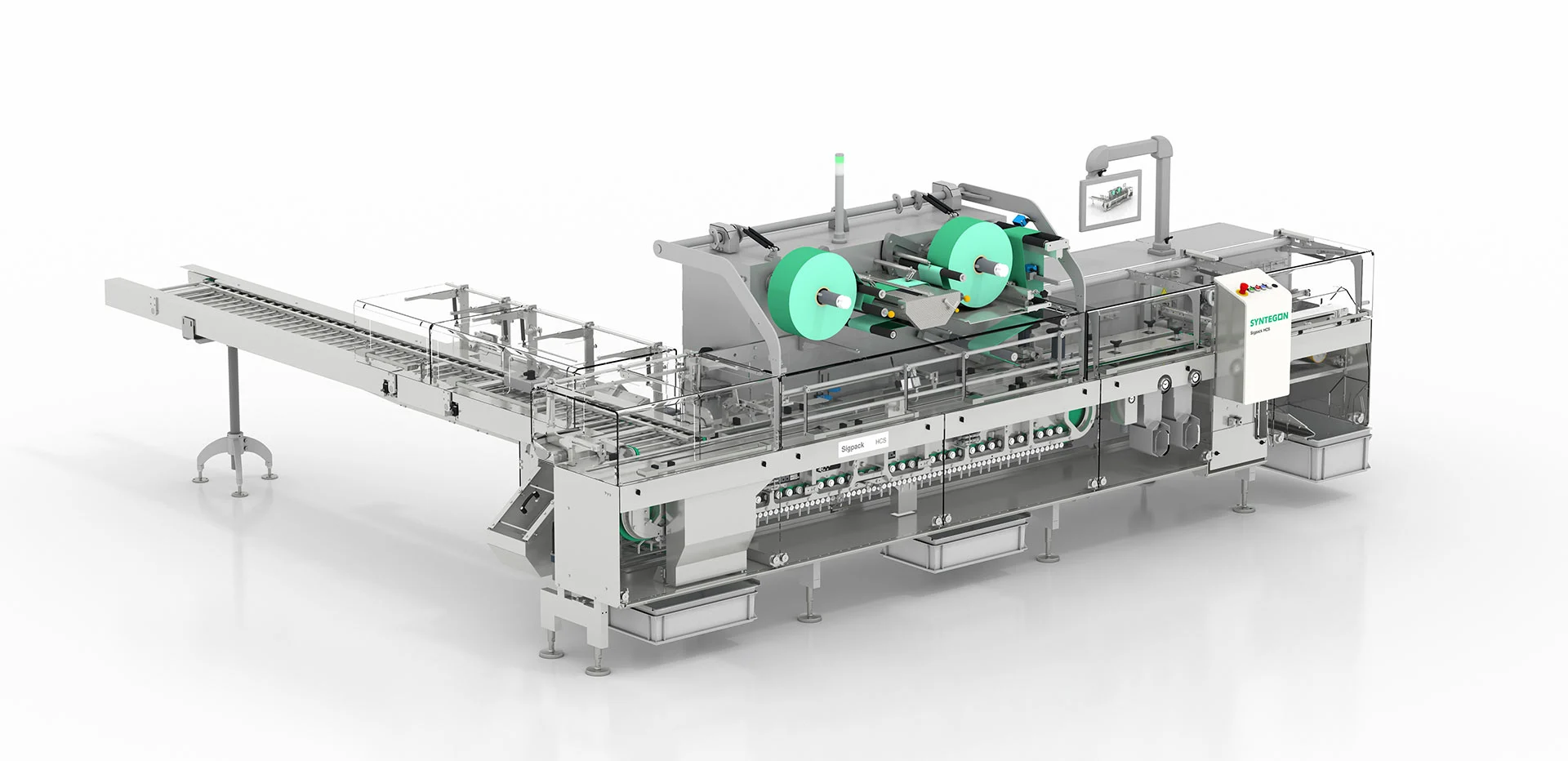

The flow wrap machine, also known as an HFFS (Horizontal Form-Fill-Seal) machine, is an advanced automated system that is used to wrap products in a fast, effective, and efficient way. It automatically wraps products in protective film. These automated machine system helps to ensure hygiene and professional presentation of products that attract customers. This machine is especially ideal for the food and personal care industries.

For example, this machine widely packs biscuits, chocolates, soaps, and tissues, attracting customers to buy the products. This modern packaging machine removes the traditional packaging system and gives high-speed packaging with minimal downtime. And it not only works faster, but it also offers you customized packaging size and design.

What Are The Key Benefits Of Flow Wrap Packaging Machines In The Packaging Industry?

The flow wrap packaging machines offer you high-speed packaging, with lower costs, product freshness, and enhanced brand presentation in the overall market. Flow wrap packaging protects your product from dust and moisture and reduces the labour cost. This is versatile in every industry to deliver efficiency, safety, and effectiveness.

High-speed packaging: The flow wrap machine is highly beneficial for packaging the products at high speed. Because the traditional packaging method can be time time-consuming process for product packaging, making the process more streamlined.

This machine is capable of packaging thousands of units per minute, and it totally depends on the machine’s capability or specifications, according to the unit. It is suitable for business owner who are looking for manufacturing or large-scale production, because their speed maintains profitability to ensure the quality of the final product.

Reduce labor costs and enhance efficiency

A flow wrap machine greatly enhances efficiency with the help of automating the entire packaging process. Because the manual wrapping is highly time-consuming wrapping every product. This machine automatically handles the entire packaging process, including handling, forming, filling, and sealing. The help of this flow wrap packaging machine reduces manual labour and all human errors.

Horizontal flow Wrap machines allow for faster machine production with minimal downtime, and continuous packaging of large volume products. It reduces manual packaging and errors. Various industries are continuously improving productivity and profitability.

Smart solution, limitless possibilities

This is the biggest advantage of flow-wrap packaging machines, and this adapts wider product range in various industries. This reduces the irregular shape of packaging, fragile foods, or dedicated confectionery to protect sensitive pharmaceutical products. These packaging machines handle all packaging for precious care.

Flow wrap packaging machines also support various material options. like polyethylene, polypropylene, and biodegradable films that give your business various attractive and sustainable goals.

This machine supports flexible formats like standard pillows, flexible packaging, quad seal pouches, or bottom bags that enhance brand recognition in the overall market.

Enhance product freshness and protection

There is another disadvantage of these packaging automation solutions for production, because these machines can seal every product tightly and ensure the product freshness, and prevent contaminants. This packaging machine is beneficial for the food and production industry, where the product quality is essential.

Because the sealing process is specialised to protect the product from moisture, air, and light. So the products can be stored for long periods.

Basically, it helps to extend the product life without excessive pressure, wear, or tear.

Branding and aesthetic appeal

These flow wrap machines enhance the functionality and the packaging opportunities of branding and aesthetic . This film is mostly used to customize quality printing and labeling, which allows your business to showcase its logo for product information and promote products in the market. This is the most adaptive component that specializes in packaging design and plays a crucial role in customer decision-making.

Reduce packaging material wastage

These machines are specialized to reduce packaging material wastage, and enhance packaging efficiency in every product manufacturing unit. High-speed flow wrap machine advances in biodegradable and recyclable materials that are committed to reducing the environmental impact.

What Are The Applications Of Flow-Wrap Packaging Machines?

This flow wrap packaging machine is used in various industries across all production units. This is the most common application to enhance production packaging in every industry.

- Food and beverage industry

- Pharmaceuticals and medical insurance

- Personal care and cosmetics industry

Why Choose Unseen Era For Flow-Wrap Packaging Machines: Optimizing Packaging Speed & Flexibility

When it talks about the packaging and industrial automation operations. Choosing the right partner is important for your manufacturing industry. At Unseen Era, we provide customized industrial automation solutions that provide you with high-speed packaging or product flexibility that drives cost effectiveness.

What we offer:

- Flow wrap packaging machines

- Industrial sensors

- Safety products

- Tower lights that enhance visual alerts on the production floors

Faq’s About Flow-Wrap Packaging Machines: Optimizing Packaging Speed & Flexibility

Question 1. How do flow wrap packaging machines increase production in the industry?

A: These machines increase production by using an automated wrapping process that allows high-speed packaging and reduces human errors. Also, this machine reduces downtime and helps to increase production quality.

Question 2. What are the benefits of using an automatic flow wrap machine?

A: The flow wrap packaging increases high-speed packaging, reduces labour costs, and improves efficiency in various product types and materials.

Question 3: How is this packaging automation solution suitable for every business?

A: This packaging solution is most suitable for every business, because it frequently handles all the product sealing, reduces labour costs, and enhances the adaptability for small businesses.

Question 4. How this horizontal wrap machine energy efficient?

A: These machines use precise sealing technology that properly optimizes the motor’s electric consumption and includes energy-saving features for modern and smart sensors to reduce wastage.

Call

Call Whatsapp

Whatsapp Contact Us

Contact Us